We use a laser Co2 for the production of parts made of PMMA and other clear materials.

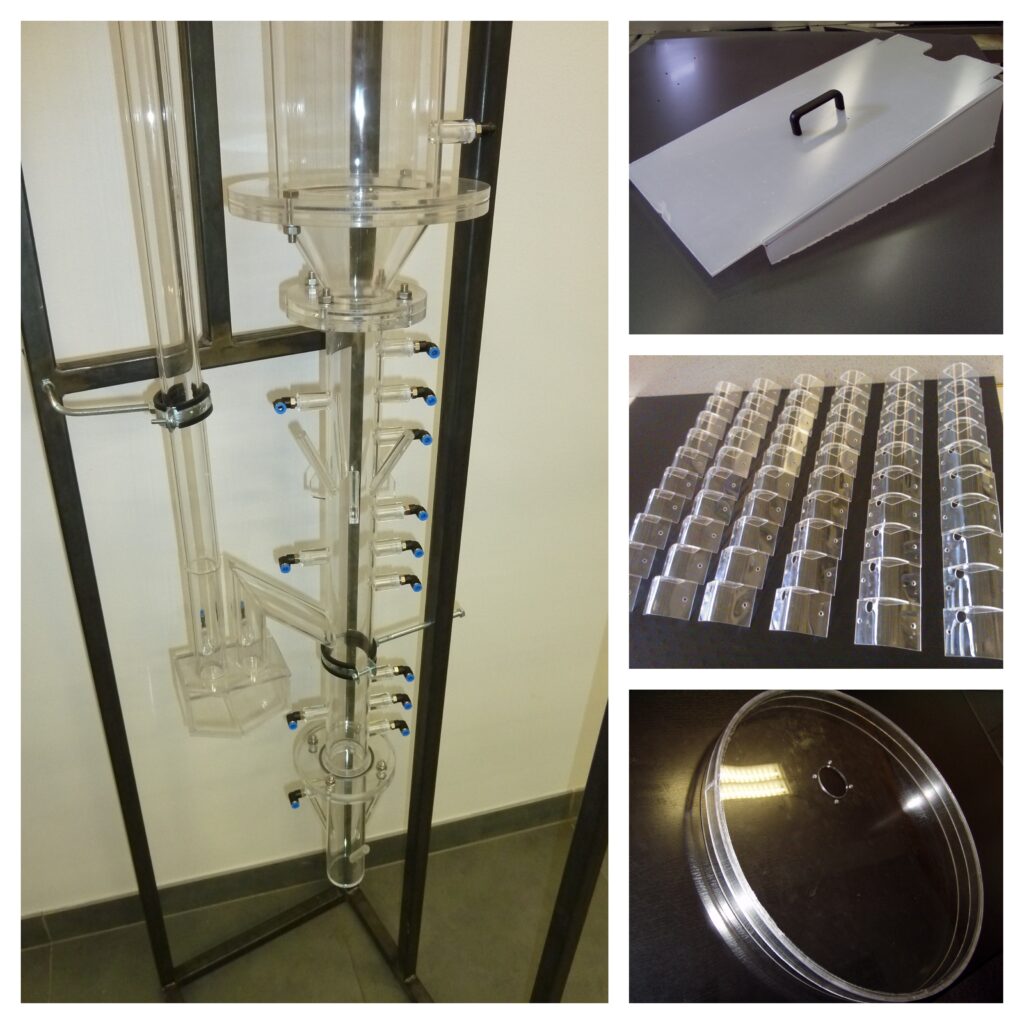

With this, we have completed our technologies for processing not only Plexiglas. This allows us to produce parts cut, laser engraved, glued, bent, hot formed, polished including flame edge polishing.

We can perform bending up to a radius of 70-80 mm.

These are, for example: tubs, stands, parts for industry – machine covers, equipment models, for advertising, for example, promotional stands, pockets for printed materials, letters and others.

We can supplement the products with parts from our 3D printing or make a prototype of the structural part. For industry, produce a strength part on a 3D printer from materials filled with carbon fiber or glass.

This is not the end of the list of our possibilities – we can weld, process different types of thermoplastics as standard and assemble a light assembly as a final product. All supported by output control, which includes 3D measurements. To make matters worse, we can also work with aluminum.

And when the going gets tough, we can also offer scanning of parts for their new production.

We do not put any restrictions on the imagination of our customers in their wishes – maybe only dimensionally – we really cannot make an airplane in real size :). Our technology and the enthusiasm of people are here for you.